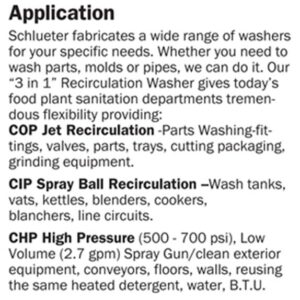

Jet Recirculation COP Washers

Schlueter Safgard Jet Recirculation Washers

Jet recirculation washers in 100, 150, 200, 250, 300 and more custom sizes. Will wash your packaging machine parts without damage and is easier, faster and of maximum economy.

In adding our Safgard sanitary baskets in numerous styles, often 12 baskets, all accommodated at one time eliminating vast handling yet holding wash solution requirements to a minimum. All machine parts, sanitary fittings, etc., are handled and washed in baskets that are sufficiently large to protect surfaces from dents and scratches. Baskets double stack.

(Pictured Left: RWJ-150 Jet Recirculation COP with CHP High Pressure Pump Unit Mtd. on Tank)

Category: Application Equipment, Clean Out of Place

More Information

Standard Features:

COP Washer Models: Series RWJ Jet Recirculation Washer Models in 100, 150, 200, 250, 300 Gallon Capacities. Larger custom sizes available.

Materials: All COP Washer parts are made of 304/316L Stainless Steel. Tank body is formed of 14 ga.

Welding/Finishing: No. 2B finish Stainless with 1″ radius corners and top edges. Parts are all weld assembled with all welds ground and polished. The Stainless piping has sanitary tri-clamp connections for easy disassembly. The formed tubular jet manifold has inspection and cleanout caps on the end, and clean-bore self-draining jets for great sanitation.

Legs/Feet: Formed of 1 ½” Stainless Tubing with adjustable ball (feet). 5″ Casters with non-marking wheels also optional.

Jet Manifold: Push-Pull Piping, Three Way Valves, and Pump Bases

Pump options: 5, 7.5, 10 and 15 HP 3/60/220/440 Motors, 3-Phase, TEFC, 3500 RPM.

CIP Capability: These washers are fitted only for COP washing as standard ordering.

- To be used for CIP work, either two additional butterfly valves with a tee installed, or two air-actuated butterfly valves, or one three way valve needs to be installed in pump discharge line.

- For all CIP work including recirculation washing of holding tanks without need for a return pump, the COP washer needs the above mentioned valves, and two port temperature control manifold in the pump suction line, and (if monitoring temperature) a steam heat tee for steam injection in the pump discharge line.

Wire Baskets: URWB-6 Standard 12 Required, Dimensions 10 ½” x 10″ x 22″ Long.

Optional Methods of Heating:

Inconel Immersion Electric Heating Elements: Mounted in tank with sealed stainless terminal box and in-tank shield.

- Electric Heater w/ case for 100 Gal. Tank w/ three 316 SS elements, 11” Long, Part #: 30505

3.5Kw, 60-250F Pilot, 480V, 3 PH - Electric Heater w/ case for 150 Gal. Tank w/ three 316 SS elements, 14” Long, Part #: 30506

5.2 Kw, 60-250F Pilot, 480V, 3 PH - Electric Heater w/ case for 200 Gal. Tank w/ three 316 SS elements, 18” Long, Part #: 30507

6.9 Kw, 60-250F Pilot, 480V, 3 PH - Electric Heater w/ case for 250 Gal. Tank w/ three 316 SS elements, 21” Long, Part # 30508

8.5 Kw, 60-250F Pilot, 480V, 3 PH - Electric Heater w/ case for 300 Gal. Tank w/ three 316 SS elements, 24” Long, Part #: 30509

10.25 Kw, 60-250F Pilot, 480V, 3 PH

Direct injection of steam through a self-actuating steam regulator: Regulator includes stainless piping, stainless thermowell, stainless steam injector, the ports in the tank, and an additional port in the tank for insertion of a recording thermometer thermobulb to be used in CIP work.

- Steam Regulators used are ½” Powers Steam Regulators – Self Actuating with stainless steel trim. ¾” , 1″, 1 ¼” and 1 ½” Powers Steam Regulators available per request.

Optional Additions for COP Jet Recirculation Systems:

COP-CIP Dual Washing:

- All jobs including Holding Tanks also need:

- One (1) three-way valve installed in pump suction line in place of tank outlet tee or two (2) butterfly valves with tee installed, or two (2) air actuated butterfly valves.

- 2 ½” two port suction manifold for recording thermometer and steam regulator thermobulbs.

- 2″ Steam Heat Tee installed in pump discharge line for steam injection with Venturi Feed.

High Pressure Pump Unit-CHP Tri-Plex Piston Pump: Reduces Labor and Improves Quality Control.

- 500-700 PSI @ 2.7 GPM, model #280 – with ¾ HP TEFC motor, Includes Base/B/P/guard, piping, suction discharge, fittings, gauge, regulator, unloader, 30′ H.P. hose, gun, nozzle and noise dampener. System mounted on a stainless steel platform.

Parts and Systems for any or all COP Recirculation Washers:

COP Recirculation Systems – Piping and Pump Bases:

Push-Pull Piping is Available for all length wash tanks: Optional for 4′, 6′, 8′, 10′, 12′ Tanks

Dual Jet System: 2 ½” x 2″ Pump, 3″ x 2 ½” Pump, Two Pump 2 ½” x 2″ for 4′, 6′, 8′, 10′, 12′ Tanks

Triple Jet System: 2 ½” x 2″ Pump, 3″ x 2 ½” Pump, Two Pump 2 ½” x 2″ for 6′, 8′, 10′, 12′ Tanks

Quad Jet System: 2 ½” x 2″ Pump, 3″ x 2 ½” Pump, Two Pump 2 ½” x 2″ for 6′, 8′, 10′, 12′ Tanks

RWJS – Jet Stream (Cross Jet and Push-Pull): Piping –Two (2) 2 ½” x 2″ Pumps w/ Butterfly Valves

- This Series/System available in 6′, 8′, 10′ and 12′ Long Sanitary Wash Tanks.

RWC – Dual Recirculation System/Valve: (Option Jet or Push-Pull with Valves)

- This Series/System available in 6′, 8′, 10′ and 12′ Long Sanitary Wash Tanks.

Air Jet Manifold available on All sizes, 4′, 6′, 8′, 10′, 12′ Tanks

Conical Dispenser option for 4′ and 6′ Tanks.

End Fan Jet Quantity (3) : Only for 6′ Tanks.

Options/Systems for Jet Recirculation Washers:

- Valve Installation for CIP – Feed Lines – Drains: 1 ½”, 2″, 2 ½”, or 3″ 11 CR Valve and Fittings

- Two (All Stainless) Butterfly Valves-Installed with tee to serve as 11 CR.

1 ½”, 2″, 2 ½”, or 3″ Butterfly Valves/Tee - Drain Valves (Butterfly All Stainless, Installed): Sizes ½”, 2″, 2 ½”, or 3″.

- Pipeline Fittings for Steam Injection and Thermowell Installation:

1 ½” or 2″ Steam Heat Tee, 2″, 2 ½” or 3″ Two-Port Manifold, and 2″ 2 ½” or 3″ Three-Port Manifolds. - Powers (Self-Actuating) Steam Regulator sizes: ½”, ¾”, 1″, 1 ¼” and 1 ½”

Available to be installed in COP Tanks, as Inline Manifolds, or as purchase of Regulator Only. - Regulator with Dial Indicator can be installed in tank for fee. ½”, ¾”, 1″, 1 ¼”, and 1 ½” sizes.

Thermowell SS p/n 32499

Mixer (Stainless Steel)

(Pictured Above: RWJ-150, 150 Gal. Dimensions: 24″ W x 74 ½” L)

Jet Stream Recirculation Washers:

(Pictured Above: Jet Stream Recirculation Washer: Model RWJS-10 Dimensions 26” w x 41” High x 11 ft 6” long)

Model RWJS-10 Jet Stream Recirculation Washer with UW-175 Gallon Tank

Model RWJS Jet Stream Recirculation Washers are tank recirculation washers serving the need for the plant having a variety of parts sizes and pipe which needs to be washed all at one time. The washer is equipped with our regular jet manifold and a push-pull piping system both of which operate simultaneously. The push-pull recirculation system operates at the lower level of the tank for clean through washing of long and short lengths of pipe placed on the tank bottom. The Jet Recirculation system gives cross-tank washing action at the upper level of the tank for washing of basket loads of machine parts or for separate discs. The tank will hold three sets of separator discs.

Each pump operates the recirculation system on one side of the tank. One pump may be equipped with a three way valve and used for CIP work while the other pump does the COP work in a limited manner. Any of the UW or RW style tanks may be used for these washers. We have selected a popular sized tank and the most universally accepted pumps.

Standard Features:

10 Ft. Ball feet, casters set of 6, or heavy duty adjustable feet

Third set of legs

Pumps: Two 7 1/2 HP 3/60/220/440

Options:

½” – 1 ½” Powers Steam Regulators available installed for in-tank heating with SS trim.

2″ – 11CR Valve: Installed in one Pump Discharge Line

Casters: Heavy duty set of six.